Rennie Scaysbrook | October 17, 2019

Arai Helmets are worn by some of the best motorcycle racers in the business, but the legendary Japanese company has always been very secretive about just what goes on behind closed doors—until now.

Shortly after our factory tour, Arai released this video that highlights its design philosophy. check that our here:

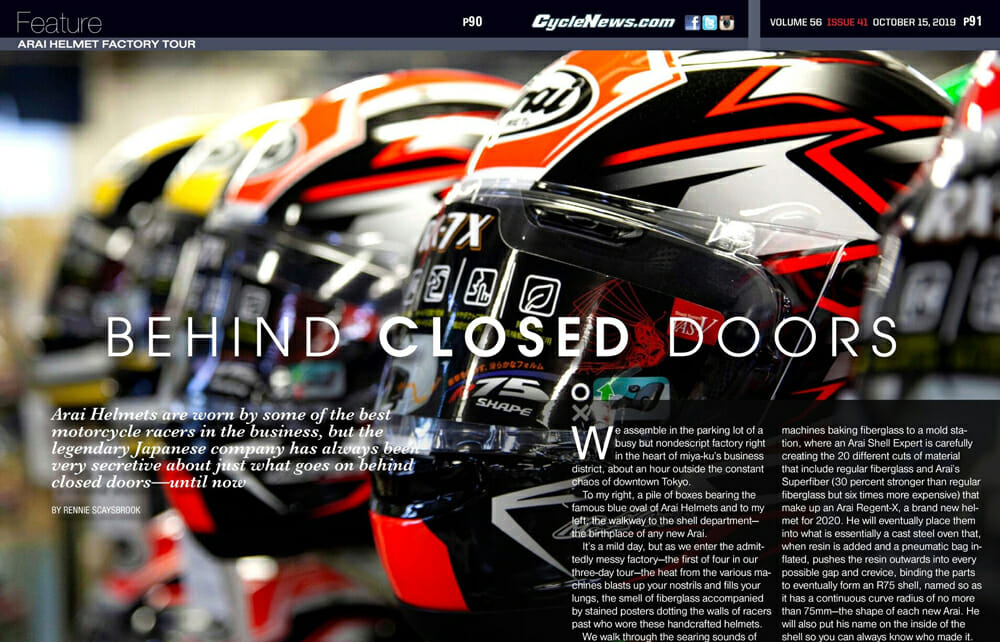

An Arai Corsair-X about to be shipped to a very happy customer. But there’s an enormous amount of work to get it to this point.

An Arai Corsair-X about to be shipped to a very happy customer. But there’s an enormous amount of work to get it to this point.

We assemble in the parking lot of a busy but nondescript factory right in the heart of Ōmiya-ku’s business district, about an hour outside the constant chaos of downtown Tokyo.

To my right, a pile of boxes bearing the famous blue oval of Arai Helmets, and to my left, the walkway to the shell department—the birthplace of any new Arai.

It’s a mild day, but as we enter the admittedly messy factory—the first of four in our three-day tour—the heat from the various machines blasts up your nostrils and fills your lungs, the smell of fiberglass accompanied by stained posters dotting the walls of racers past who wore these handcrafted helmets.

We walk through the searing sounds of machines baking fiberglass to a mold station, where an Arai Shell Expert is carefully creating the 20 different cuts of material that include regular fiberglass and Arai’s Superfiber (30 percent stronger than regular fiberglass but six times more expensive) that make up an Arai Regent-X, a brand-new helmet for 2020. He will eventually place them into what is essentially a cast steel oven that, when resin is added and a pneumatic bag inflated, pushes the resin outwards into every possible gap and crevice, binding the parts to eventually form an R75 shell, named so as it has a continuous curve radius of no more than 75mm—the shape of each new Arai. He will also put his name on the inside of the shell so you can always know who made it.

Fiberglass and Superfiber are blasted onto a dome the shape of a human head to create something similar to a bird’s nest, known as the preforma, which will form the basis for any Arai shell.

Fiberglass and Superfiber are blasted onto a dome the shape of a human head to create something similar to a bird’s nest, known as the preforma, which will form the basis for any Arai shell.

The Shell Expert must work fast. The resin used is good for six hours from the minute it is mixed, and while that may seem like a long time when you factor in a Shell Expert can knock out about 100 shells a day and the amount of resin that requires, everything is a time-restricted science.

The shell is cooked for 15 minutes, and a senior Shell Expert will have five on the go at once—all in various stages cooking. At the end of the baking process, an initial inspection will take place, and if the shell passes, it will be sent to a kiln and baked for a further three hours at 65°C (150°F). It will then be sent across town to the Amanuma facility for a second, final inspection, after which the Shell Inspector’s name is placed on the inside of the finished product. Pull your EPS liner out at the end of your Arai helmet’s life, and you’ll be able to see who made it.

These 20-odd parts are what make up a Regent-X shell before baking.

These 20-odd parts are what make up a Regent-X shell before baking.

Watching this shell creation is a mechanically beautiful thing, and this is just the beginning of any Arai’s life. There’re another 35 or so steps in the process, including quality inspections at every stop before the helmet reaches completion. Fail at any point, and it’s all for nothing. There are huge potential losses in materials and labor if a shell gets to the final stage of boxing and there’s a problem.

Despite the various machines that dot the factory floor all around me, it’s immediately apparent the human touch is absolutely essential to Arai’s philosophy. A company with almost 400 employees spread across four factories in Ōmiya-ku, the major manufacturing plant in Shinto, the Katayanagi assembly plant and another facility at Amanuma, Arai still firmly believes in human accountability over letting machines and algorithms do most the work.

We were not allowed to take photos of the shell department. However, an employee is here demonstrating the process of layering the fiberglass for the shell prior to baking.

We were not allowed to take photos of the shell department. However, an employee is here demonstrating the process of layering the fiberglass for the shell prior to baking.

Unlike many helmet manufacturers, Arai has complete control over every step from the first laying of fiberglass to the boxing of a freshly finished helmet. Almost nothing is outsourced, nothing left to chance.

It’s been this way forever since founder Hirotake Arai created a hard-hat company that would eventually be used for the Japanese Imperial Army in World War II. A bit of a maverick, Hirotake is the guy depicted in the famous photo of the young man in a top hat standing on the seat of a moving Harley-Davidson that Arai uses in its advertisements.

“Those people [soldiers] over in southeast Asia were fighting in the hot weather,” says Arai Helmets 81-year-old president and CEO—and Hirotake’s son—Mitchio [Mitch)] Arai, who will soon pass the company onto his son, 45-year-old Akihito Arai.

“They needed some heat isolation. My father came up with a hat using bamboo. The Japanese army liked that idea, so they asked him to do some more for them. But he did not make helmets—there was a company in Tokyo doing that for the army.”

Mr. Arai, better known at Mitch Arai, with his late father in the background riding on the seat. “I think my father needed a helmet, he crashed more than me!” Arai says.

Mr. Arai, better known at Mitch Arai, with his late father in the background riding on the seat. “I think my father needed a helmet, he crashed more than me!” Arai says.

Arai’s first manufacturing plant, on the site where our story began, opened in 1937, the only large scale factory in a sea of farming and agricultural land. It was a far cry from the bustling metropolis Ōmiya-ku is now.

Following the cessation of hostilities, in the early 1950s, Arai became the helmet manufacturer we all know today. At the time, it was near impossible to import a helmet as the country rebuilt from the war, so it fell on Hirotake to make a helmet himself. The company was initially called HA (Hirotake Arai) and only changed its name to Arai late in the 1960s.

Hirotake can also take credit for the creation of what would become the basis for almost every motorcycle and car helmet for all brands to follow in the implementation of the foam EPS liner. Interestingly, the American manufacturer Bell Helmets had come up with the same idea at roughly the same time (the two companies can’t agree on who got there first, despite never having heard of each other at the time of the EPS’ creation). Yet there was no bad blood between Arai and Bell, and the two iconic brands share a mutual appreciation to this day.

It wasn’t until Mitch joined the company in the 1960s as a young man just returned from an American education that Arai shifted its focus to become a world motorsports leader. Mitch had competed on a semi-pro level, knew the market, and knew what racers wanted and needed in a helmet.

It was also the time the famous Arai shape was born.

Arai’s Egg-Shaped Form (ESF) is core to the design principle. Like an egg—the strongest form in nature—the ESF narrows at the bottom, similar to the shape of the human skull. This helps to maintain the shell’s integrity in a crash and has been in constant evolution since Arai put it on the market when the Complex Laminate Construction shell was first sold in 1977. It’s no coincidence if you look at Freddie Spencer’s 1983 500cc World Championship-winning Arai, it bears a close resemblance to the one Nicky Hayden won the 2006 MotoGP title with and the one Maverick Vinales wears now.

Computer laboratories help scan a newly hand-sculpted shell design to ensure it’s as perfectly symmetrical.

Computer laboratories help scan a newly hand-sculpted shell design to ensure it’s as perfectly symmetrical.

The ESF is also one of the main factors at the heart of the current helmet industry—rotational impact absorption. Arai argues its sphere-like shape offers its own form of rotational impact absorption, known as “glancing off” in company speak, as it doesn’t allow any sharp points on the helmet that could catch and thus pull the helmet (and therefore, the rider’s head) in any one direction. Combining a deforming outer shell of about three millimeters in width with the egg shape and multi-density, 40mm thick EPS liner crush, the idea is the helmet will both deflect and absorb most forces before they ultimately get into your head.

To this end, the vents are light and glued on, while the spoiler on a Corsair-X is designed to sheer off. In a tumbling fall, all the extra parts on the helmet will break off, and you’ll be left with an egg shell protecting you against the elements, sliding over or glancing off objects, just as was intended all those years ago.

“Absorption is the last line of defense,” says Arai Americas Managing Director, Brian Weston. “Your first line of defense is a strong, round, smooth shell that slides to avoid or reduce crash energy before it gets inside the helmet. You never know what angle, what speed, and what energies are going to come in an impact, so we design the helmet to basically address almost everything we can imagine.”

Arai Americas’ general manager Brian Weston with the full lineage of Arai shells, starting left to right. See the third, half brown shell? That was a full Kevlar shell, experimented with back in the early 1980s, that was ditched due to time, weight, and expense of manufacturing.

Arai Americas’ general manager Brian Weston with the full lineage of Arai shells, starting left to right. See the third, half brown shell? That was a full Kevlar shell, experimented with back in the early 1980s, that was ditched due to time, weight, and expense of manufacturing.

Arai is not against implementing something like the MIPS rotational impact-absorption system currently found in helmets like the Bell Race Star, but it’s still too early in the research for the Japanese giants to go ahead with it.

“A smooth shell can slide across its entire surface, avoiding or minimizing rotational force and reducing impact energy before it gets into the helmet where the liner must absorb it,” says Weston. “Rotational mitigation technology inside a helmet has a limited range or distance that it can travel and therefore try to manage rotation.

“Additionally, material from the helmet’s liner must be traded to incorporate this rotational technology, in effect reducing its capacity to absorb, unless you increase the helmet size to add more material back in.

“Dealing with energy outside the helmet, before it gets inside, is where Arai prefers to deal with impact and rotational energy. With such a limited material inside with which to absorb the impact energy that does get inside—our goal is to keep it out—not try to deal with it once it gets in.”

Although it may seem like Arai is refusing to move with the times, the company told us they will not put any new element into a helmet until it is guaranteed to improve the finished product. That’s another reason why the shape barely changes—it’s better to continually, but slowly, improve one design over decades than to start fresh every few years. The continual small steps have one significant benefit to manufacturing; that being, if one step is wrong and doesn’t improve the product, Arai has only to go back one step to a platform they know works.

Another Nicky 7 gets ready for a new visor.

Another Nicky 7 gets ready for a new visor.

“We’ve built the helmet as an energy management system, with each component designed based on all the other components, both the shell and inner liner building upon and supporting the other,” says Weston. “To introduce a new design idea can dramatically offset the balance and performance that Arai has evolved over the decades. We know our system has shown incredible performance across those decades, so we are careful not to leap blindly at new tech no matter how trendy it may be.”

One of the big changes of late came from Arai’s Formula One department in the Hyper Ridge, which is a step in the shell designed to stop cracks that can appear when you crash, and the helmet is impacted. Another is the use of Specialized Glass Fiber, or Zylon, a material found in bulletproof vests and located at the crown of the helmet, lowering the helmet’s center of gravity and weight, which in turn reduces rider fatigue.

See the dark belt at the eye port? That’s the new Peripheral Belt, made from Superfibers, to increase the strength around the most vulnerable area of the helmet without increasing weight.

See the dark belt at the eye port? That’s the new Peripheral Belt, made from Superfibers, to increase the strength around the most vulnerable area of the helmet without increasing weight.

Arai Helmets Factory Tour | The Next Step

Once our shell has had the eyeport cut out (the only part of the process to be done entirely by machine), been through the baking process, and passed the two rigorous inspections, it’s then shipped to paint.

The painting process involves 10-15 steps, depending on the model being created. These include an initial hand buffing and primer coating, another trip to the oven for a bake, and three different stages of wet sanding, all of which get their own primer. The labor required to produce just one helmet is immense, with the initial base paint taking three days per color—one for masking, one for painting and sanding, and one to layout the water graphics.

A machine laser cuts the eye port. This is one of the very, very few steps that is trusted to a machine and not human hands.

A machine laser cuts the eye port. This is one of the very, very few steps that is trusted to a machine and not human hands.

It’s important to note each shell is designed to have the maximum amount of fiberglass and the minimum amount of resin, part of the reason the first surface is rough and requires so many steps to get it ready for paint. If the helmet has more resin than needed, the surface would be smoother, but the helmet itself would be heavier and weaker.

After leaving the second baking station, it’s time to get sanding.

After leaving the second baking station, it’s time to get sanding.

By the time it’s ready for the graphics, the helmet will have gained 25 grams in weight, equivalent to about the weight of four quarters. But then comes an interesting piece—the wet layering of graphics—done almost exclusively by female hands.

Getting a Nicky Hayden or Dani Pedrosa replica to look the way it does is an exacting process, one on that is completed almost entirely by women. Arai says its female graphics workers have more patience, more finesse, and ultimately do a better job at laying the intricate sheet graphic designs than their male counterparts, who can get agitated too quickly and thus don’t do as good a job.

If watching a shell being created is beautiful in an industrial sense, seeing these ladies take a plain white Arai Corsair-X and craft it into a Doohan, Nakagami, or Roberts replica is gorgeous in the artistic sense.

By stage three of the post-baking prep, and after hours of getting the shell down to a smooth surface, final wet sanding is done before paint/graphics.

By stage three of the post-baking prep, and after hours of getting the shell down to a smooth surface, final wet sanding is done before paint/graphics.

It’s eerily quiet as they work. Only the sounds of moving trollies and the machine in the background popping rivets for the chin strap locators breaking the silence in the cleanest area of any of the four Arai factories we visit.

Nearly all the graphics are laid by hand, although some, like the Freddie Spencer 30th Anniversary Corsair-X, are painted by hand. And yes, every helmet is given a final spray and polish by hand.

Graphics layering is an incredibly intricate and time-consuming process.

Graphics layering is an incredibly intricate and time-consuming process.

“We are not very good businessmen,” Mitch Arai says in an entirely self-effacing manner. “We understand that many of the processes we do will cost us money, but we believe in them because they are not carried out by machines—they carried out by our people.”

An example of this is the man who fits the EPS liner. After the shell is drilled for the visor, chin strap, and ventilation points, the helmet is sent to the EPS employee who carefully pushes the multi-density EPS liner into the shell, lining up the vent holes and getting it ready for the final stages in construction that include fitting the chin straps, inner cheek and head liners, visor, and vent fitment and boxing.

Typically, a machine would do this EPS fitting, but Arai believes no machine can do this task better than two human hands, which contributes to the expense, but also the quality of the finished product.

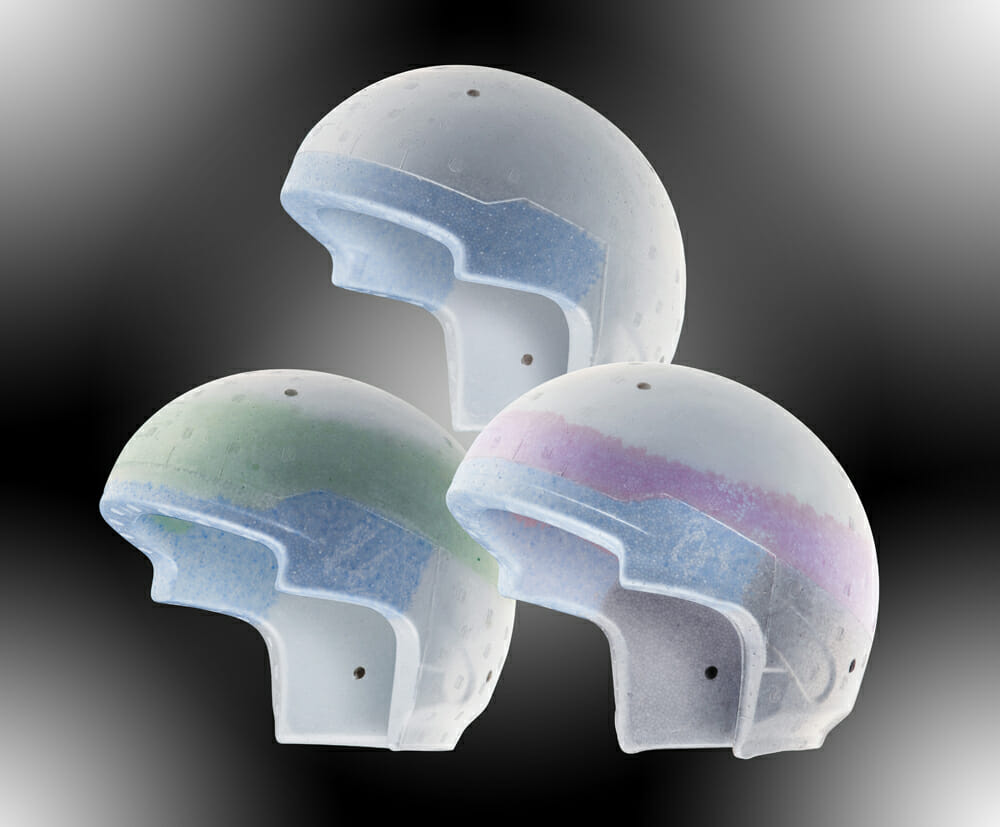

Arai’s foam EPS liner. You can see the various densities, starting with the higher density up front that gradually gets softer as it goes further up the liner.

Arai’s foam EPS liner. You can see the various densities, starting with the higher density up front that gradually gets softer as it goes further up the liner.

Once the helmet has been fitted with the interior, including cheek pads, top liner, riveted double D-ring retention system, and chin bar, its sent to packing for what is likely to be its final journey to the customer. I say likely because there’s still a chance it will be pulled at random and used for testing to ensure it meets the various standards so it can be sold legally across the world.

Arai doesn’t construct special helmets for testing, as Mitch Arai showed us by pulling a helmet from the production line and strapping it to their own testing facility in Omiya. In this specially constructed room around the corner from the shell construction area we started today in, sits a machine that can reach as high as 16 feet, and provide the most stringent testing for high impacts anywhere in the world.

The EPS liner technician can knock out about 250 jobs a day if he’s on it. Getting the liner in is all about technique rather than brute strength.

The EPS liner technician can knock out about 250 jobs a day if he’s on it. Getting the liner in is all about technique rather than brute strength.

If you want your helmet to pass DOT standards, it’ll need to test with results below 400 G, while the Snell test is 275 G. With a Japanese model Rapide-IR fitted to the raising arm, the Arai was dropped from 10 feet and registered 182 G, easily passing the DOT test.

To be Snell certified, another test had to be performed but from a lower height of eight feet. Again, it came back at 182 G, which was remarkable given it’d already absorbed such a massive hit first time.

And finally, we were ushered into the shell-penetration test room, with a menacing-looking steel rod with a pointed end that’s designed to literally go straight through the helmet and into your brain via the shell and weak points in the vents.

Arai’s testing facility ensures the helmets will pass any test thrown at them.

Arai’s testing facility ensures the helmets will pass any test thrown at them.

Snell requires a drop from 10 feet, while the Formula One FIA8860 requires a drop from 13 feet. The Arai tech then dropped our helmet from 16 feet, and the rod hit the helmet three separate times, and nothing got through to the EPS liner. An interesting tidbit was the helmet used for testing was a motorcycle helmet, not a Formula One helmet, and it still passed.

Watching the test hammered home just how much abuse a helmet must take, and these impacts are defined and repeatable, while a motorcycle crash on the street or track can be completely unpredictable. And I should know, I’ve had many. In a way, it can almost make your stomach turn, but it’s also reassuring to see the kinds of impacts an Arai is capable of withstanding before it reaches the mushy stuff between your ears.

Despite surpassing the various tests at the Arai facility, it’s a fact of life that no helmet can protect against all accidents. Arai is uncomfortable with this facet of the job but knows through the enormous channels of human labor and quality control they have done their absolute best to make the most protective helmet possible for your head.

“We are truly obsessed with protecting people. This isn’t a gimmick,” says Weston. “We can’t do it cheaply. We won’t do it with robots.”

Indeed so. When I started this job as a motorcycle writer 15 years ago, I never thought I’d get the chance to visit the factory of the helmet I had my first highside crash in. That crash was a belter, everything was sore, the helmet was trashed, but it did its job absolutely perfectly. The Arai facilities we visited, as well as two-day ride thanks to Honda Motorcycle Japan (more on that in the gear review of the new Regent-X coming soon), showcased just how important Arai is not only to the people running the company but especially the workers.

Rennie asks Aki Arai when the Cycle News replica is coming. Short answer, never.

Rennie asks Aki Arai when the Cycle News replica is coming. Short answer, never.

Everyone needs a job, but the immense pride these men and women have in their work was evident from the Shell Experts to the wet sanders, the graphics ladies, and particularly the man boxing the helmets at the end, who did it with Ninja-like speed (I think he was showing off a little for the assembled journalists).

The human touch will always have more meaning than that of a robot, and I’ll admit to not appreciating just how many people and departments are involved in making an Arai what it is. The blue oval at the front of my street Corsair-X now has a lot more meaning to me than it did before.CN